Low Carbon Hydrogen from Composites

Rethink

Rotor Blade Recycling

It is our mission to revolutionize the wind power industry through sustainable blade recycling.

In a nutshell

Joulmine’s innovative recycling process frees the wind industry from having to choose between economic viable solutions and sustainability.

WHy?

Rethinking wind rotorblade recycling is essential as over 200,000 tons of GFRP scrap are generated in Europe each year from various industries, with a significant portion originating from decommissioned wind turbine blades. Current practices, such as incineration and limited recyclate reuse, either contribute to emissions or defer the recycling challenge.

As a substitute for fossil fuels, hydrogen plays a key role in decarbonisation and thus in achieving climate goals. Hydrogen is therefore an essential part of a sustainable future. Demand is set to grow in various sectors. To meet this demand and provide sufficient hydrogen, industrial solutions are needed. By converting industrial waste products into hydrogen, we contribute to this mission.

What we do

We specialize in an innovative, IP-protected process that effectively separates glass fibers from epoxy and polymers, enabling us to recycle glass, regenerate carbon for new product applications, and produce hydrogen from clean synthesis gas.

Full Material Recovery

By fully recovering all materials, we transform the wind industry into a fully circular ecosystem.

Zero Emissions

Reducing the CO2 footprint and emissions across the lifespan of installations.

Low Carbon Hydrogen

We are outperforming green hydrogen from electrolyzers in carbon footprint.

Carbon as a Raw Material

Emitting CO2 gas is wrong. We must prioritize regeneration and reuse of our existing resources.

Renewably Powered

Renewables for Recovery of renewable materials.

Scalable and economically viable

Choose environmentally friendly disposal without breaking the bank.

Resource Mining.

Solving Big challenges

Resource mining complements waste management by extracting valuable secondary materials from long-lasting goods. This approach not only provides economic benefits amidst rising resource competition but also promotes environmental sustainability. By recycling high-value materials, resource mining conserves natural resources and supports the well-being of current and future generations.

Industrial scale.

High technical readiness

Start of comissioning

Capacity of GFRP Recycling

Low Carbon Hydrogen

Carbon Captured

Why it Matters

For our future on this planet, decarbonisation must take place across a wide range of sectors. This applies not only to the energy sector, but also to industry, transport and buildings. Extreme challenges require unique approaches – thus we have set out to make it work!

INGENUITY

Doing more with less

We believe it’s possible.

“When you don’t have resources, you become resourceful.” KR Sridhar (Chief Executive Officer, Bloom Energy)

100%

Make wind turbines 100% recyclable : Wind turbines are built and run to fight climate change. Let’s achieve this goal from start to finish!

RESPONSIBILITY / DUTY OF CARE

Entrepreneurial responsibility: Our mission is inspired by Kellie McElhaney of the University of California: “It’s not about how you spend the money you make. It’s how you make the money you spend.”

NEXT GENERATION

For our children: The youngest generation deserves to grow up in a world with solutions to the problems created by previous generations.

NET ZERO /CO2 NEUTRALITY

CO2 | Net Zero: Production and recycling processes can be 100% CO2 neutral and 0% circular. We need to start redesigning all products to be 100% circular to conserve virgin resources. Our goal is to be 100% CO2 neutral and to recycle every element of the rotor blades.

Closing two loops

Full sustainability requires us to close all loops in the recycling cycle. While many methods focus solely on the material cycle, they often overlook the critical energy cycle. Our processes address both the material and energy cycles, ensuring a comprehensive approach to sustainability.

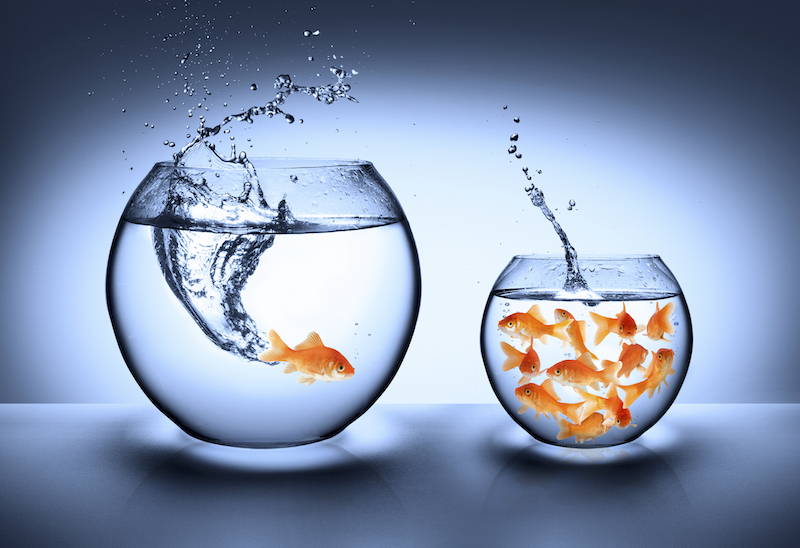

Are You Ready to Dive Into Energy Conversion?

Than join the waiting list.

Feel free to write to us

contact@joulmine.com

Find us

Hartwigstrasse 41, 28209 Bremen